قائمة المنتجات

Metal Open-end Hit Backside Zipper Machinery (Auto Line)

- السيارات المعدنية فجوة ع.ح وآلة تجريد (TYM-210M)

ويستخدم معدن السيارات سحاب فجوات وآلة تجريد لإزالة الأسنان من سلسلة سستة المعدنية وتحديد المطلوب طول سستة النهائي....

Tag:

- السيارات بالموجات فوق الصوتية فيلم آلة لحام (TYM-205M)

اعتمد المعادن السيارات آلة فيلم لحام لحام أفلام مزدوجة لالسوستة المعدنية بعد فجوات، والتي تعتمد على جهاز خاص في المكان الذي قطع المطاط من أجل حل رئيس يموت من السهل مشكلة المكسورة....

Tag: آلة زيبر فيلم معدنية لحام | السيارات المعدنية بالموجات فوق الصوتية السينمائي آلات اللحام | المعادن بالموجات فوق الصوتية لحام فيلم زيبر ماكينة | السيارات بالموجات فوق الصوتية فيلم معدات لحام النايلون زيبر

- المعادن السيارات المفتوح نهاية آلة التثقيب (TYM-209M)

يستخدم المعدن لصناعة السيارات في نهاية مفتوحة آلة تثقيب لكمة ثقوب في سحاب معدنية لوضع الدبابيس والصناديق....

Tag: المعادن الضرب سحاب آلات صنع | السيارات المعادن المفتوح نهاية معدات التثقيب | مفتوح إنهاء معدن سحاب الضرب الآلات | المعادن الضرب زيبر معدات

- السيارات معدن دبوس وآلة إصلاح صندوق (TYM-203M)

السيارات مسمار معدني ومربع تحديد الجهاز قادر على إدخال وتثبيت دبوس ومربع لسستة نهاية مفتوحة. ويمكن إرسال رقم التعريف الشخصي ومربع تلقائيا إلى خفض تكلفة العمل وزيادة الكفاءة....

Tag: السيارات الدبوس وصندوق إصلاح آلة معدنية سحاب | المعادن المفتوح نهاية دبوس وصندوق آلات إصلاح | فتح نهاية دبوس وصندوق معدات إصلاح | السيارات الدبوس وصندوق إصلاح زيبر ماكينة

- السيارات المعدنية المتزلج آلة تركيب (TYM-224M)

يتم تطبيق آلة تصاعد المنزلق السيارات لادخال المتزلجون على سلاسل سحاب لاتجاهين السوستة المعدنية نهاية مفتوحة. يجب شق سلسلة قبل إدخال المتزلجون....

Tag: معدن سحاب المتزلج معدات تركيب | المعادن المتزلج تركيب سحاب ماكينة | السيارات معدن سحاب المتزلج آلات تركيب | المعادن المتزلج تركيب سحاب معدات

- السيارات معدن مزدوجة الأعلى وقف آلة (TYM-215M)

ويستخدم معدن السيارات مزدوجة الأعلى وقف آلة لقطع الأسلاك النحاسية وتحديد بالضبط مزدوجة أعلى توقف لالسوستة المعدنية. مصنوعة أعلى نقاط من أسلاك النحاس توقف. U أعلى وقف آلة تحديد للسحاب معدنية متوفرة....

Tag: قمة ثنائية إيقاف معدات لأشغال معدنية سحاب | السيارات معدنية مزدوجة الأعلى إيقاف زيبر الآلات | المعادن السيارات مزدوجة الأعلى إيقاف زيبر صنع الآلات | السيارات معدن سحاب مزدوجة الأعلى إيقاف معدات

- السيارات معدن سحاب U الأعلى وقف آلة (TYM-232M)

السوستة المعدنية للسيارات U أعلى وقف آلة يمكن اصلاحها على وجه التحديد مزدوجة U أعلى سدادات لالسوستة المعدنية. آلة واحدة لا يصلح إلا لحجم سحاب واحدة. أعلى آلة توقف من الأسلاك النحاسية للسحاب معدنية متوفرة....

Tag: السيارات معدن سحاب U الأعلى إيقاف معدات | المعادن U الأعلى إيقاف معدات | آلة U المعادن الأعلى التوقف عن معدن سحاب | المعادن U الأعلى إيقاف سحاب آلات صنع

- المعادن السيارات المفتوح نهاية آلة قطع (TYM-220M)

يستخدم المعدن لصناعة السيارات في نهاية مفتوحة آلة قطع لقطع سلسلة سستة إلى قطع في شكل مستقيم. سحاب لصناعة السيارات في نهاية مفتوحة آلة قطع مع أنواع المتزلجون متاح....

Tag: السيارات زيبر المفتوح نهاية آلات القطع | السيارات المعادن المفتوح نهاية معدات قطع | السيارات معدن سحاب آلات القطع | السيارات مفتوح نهاية معدات قطع للمعادن سحاب

Description

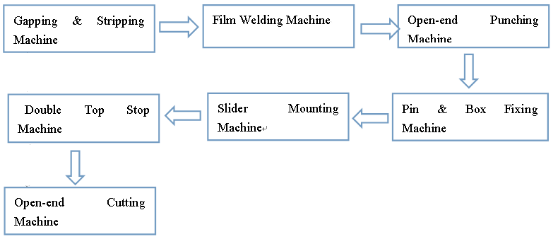

gapping and stripping machine, film welding machine, open-end punching machine, pin and box fixing machine, slider mounting machine, double top stop machine and open-end cutting machine. These machines work together to finish hit backside open-end metal zippers.Advantages of Metal Open-end Zipper Making Machine

1. Slider mounting mold can be used for sliders in different height of puller lock without adjusting hook and other parts.2. Extra spare parts of each machine will be packed in tool box and sent together with machine when make delivery.

3. The unlock part of the mold can be adjusted automatically and then balanced, which is suitable for special common and special puller.

4. Locating system adopts active transmission device, which can realize bottom stop inducing function.

Note of Auto Metal Open-end Hit Backside Zipper Line

1.The automatic machines works in high efficiency, helping to save lots of labor source and cost, while the efficiency of semi-auto machine is lower than automatic one, but they are more easier to operate and maintenance.2. Usually one worker can operate 3 to 4 automatic metal open-end zipper making machines at the same time, while semi-auto machines need one worker for each machine.

(The choice of automatic machine or semi-auto machine depends on customer’s actual situation.)

Flow Chart of Auto Metal Open-end Hit Backside Zipper Line

Machines used for Auto Metal Open-end Hit Backside Zipper Line in Tianyi

| 1.TYM-210M | 2.TYM-205M | 3.TYM-209M |

| 4.TYM-203M | 5.TYM-224M | 6.TYM-215M or TYM-231 |

| 7.TYM-220M |

|

|

English

English Russian

Russian Spanish

Spanish