قائمة المنتجات

Metal Open-end/Two Way Hit Backside Zipper Machinery (Semi-auto Line)

- السيارات المعادن فجوة ع.ح وآلة تجريد (TYM-210M)

يتم استخدام السيارات فجوات المعدنية وآلة تجريد لإزالة الأسنان من سلسلة سحاب معدنية ووضع المطلوبة طول سستة النهائي....

Tag:

- السيارات بالموجات فوق الصوتية آلة لحام فيلم (TYM-205M)

السيارات بالموجات فوق الصوتية آلة لحام فيلم قادرة على حام أفلام مزدوجة لالسوستة المعدنية بعد فجوات. في المكونات الكهربائية الرئيسية هي من اليابان وألمانيا وتايوان، الخ...

Tag: السيارات بالموجات فوق الصوتية لحام فيلم سحاب معدات صنع | فتح نهاية الفيلم ماكينة لحام زيبر صنع | فتح نهاية معدات الموجات فوق الصوتية والأفلام لحام | آلة السيارات المفتوح نهاية الفيلم لحام

- السيارات آلة الضرب المفتوح نهاية (TYM-209M)

يستخدم معدن السيارات مفتوح نهاية آلة تثقيب لكمة ثقوب في سحاب معدنية لوضع الدبابيس والصناديق....

Tag: سحاب الضرب صنع معدات لأشغال معدنية سستة | المعادن المفتوح نهاية آلات التثقيب | المعادن آلة التثقيب | معدن سحاب آلة التثقيب

- شبه التلقائي ضرب المؤخرة دبوس وضع آلة (TYM-204M)

ضربت نصف السيارات يتم تطبيق المؤخر آلة وضع دبوس لوضع دبوس (اللكم الجانب الخلفي) للسحاب معدنية. بهيكلها البسيط وتصميم معقول، وهذا الجهاز سهل التشغيل والصيانة....

Tag: معدن دبوس وضع سحاب معدات | شبه التلقائي ضرب المؤخرة دبوس ماكينات إعداد | العقلية زيبر دبوس آلة وضع | معدن دبوس وضع زيبر ماكينة

- شبه التلقائي آلة إعداد مربع (TYM-204M2)

ضربت شبه السيارات مربع المؤخر وضع الجهاز يستخدم لمربع (اللكم الجانب الخلفي) وضع لالسوستة المعدنية. آلة أوتوماتيكية هو متاح أيضا....

Tag: صندوق معدني آلة وضع | شبه التلقائي معدات إعداد الإطار | شبه التلقائي ضرب المؤخرة صندوق معدات إعداد | صندوق شبه التلقائي وضع آلية لمعدن سحاب

- دبابيس مزدوجة شبه التلقائي وضع آلة (TYM-217M)

تم تصميم شبه التلقائي دبوس مزدوج آلة الإعداد لتعيين دبابيس مزدوجة (اللكم الجانب الخلفي) للاتجاهين نهاية مفتوحة المعادن سستة....

Tag: معدات مزدوجة وضع دبوس للمعادن سحاب | شبه التلقائي مزدوج دبوس ماكينات إعداد | معدن مزدوجة دبوس وضع سحاب معدات | معدن زيبر مزدوج دبوس آلة وضع

- شبه التلقائي آلة قطع المفتوح نهاية (TYM-202M)

ويستخدم نصف السيارات مفتوح نهاية آلة قطع لقطع سلسلة سحاب الى قطع في شكل مستقيم. آلة أوتوماتيكية هو متاح أيضا....

Tag: المعادن المفتوح نهاية القطع زيبر ماكينة | فتح نهاية قطع سحاب معدات صنع | نصف السيارات المفتوح نهاية آلات القطع | آلة قطع المفتوح نهاية المعادن

- نصف السيارات أعلى آلة إيقاف (TYM-213M)

شبه التلقائي آلة معدنية توقف قمة قادرة على خفض وتحديد أعلى نقاط مزدوجة لالسوستة المعدنية. بهيكلها البسيط وتصميم معقول، وهذا أعلى آلة معدنية توقف سحاب سهلة لتشغيل وصيانة....

Tag: شبه السيارات المعادن الأعلى إيقاف الآلات | المعادن المفتوحة نهاية آلة الأعلى إيقاف سحاب | فتح نهاية آلة الأعلى التوقف عن معدن سحاب | المعادن الأعلى إيقاف زيبر معدات صنع

Description

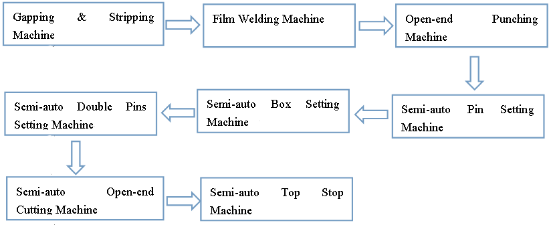

gapping and stripping machine, film welding machine, open-end punching machine, semi-auto pin setting machine, semi-auto box setting machine, semi-auto double pins setting machine, semi-auto open-end cutting machine and semi-auto top stop machine. These machines work together to finish backside one-way and two-way open-end metal zippers.Advantage of Metal Hit Backside Zipper Making Machine

1. Most of our components use brands from Taiwan and Japan, such as AIRTAC, MINDMAN, DELTA, in order to ensure longevity and stability.2. Film welding part position can be adjusted depending on different zipper requirement.

3. Fully auto device with easy operation and high stability, which can reduce your cost and workforce by 3 times.

4. CD, operation video and circuit diagram are about how to operate and maintain machine.

5. Overseas training can be provided.

Note of Semi-auto Metal Two Way Hit Backside Zipper Line

1. The automatic machines works in high efficiency, helping to save lots of labor source and cost, while the efficiency of semi-auto machine is lower than automatic one, but they are easier to operate and maintenance.2. Usually one worker can operate 3 to 4 automatic machines at the same time, while semi-auto metal hit backside zipper making machines need one worker for each machine.

(The choice of automatic machine or semi-auto machine depends on customer’s actual situation.)

Flow Chart of Semi-auto Metal Two Way Hit Backside Zipper Line

Machines used for Semi-auto Metal Two Way Hit Backside Zipper Line in Tianyi

| 1.TYM-210M | 2.TYM-205M | 3.TYM-209M |

| 4.TYM-204M | 5.TYM-204M2 | 6.TYM-217M |

| 7.TYM-202M | 8.TYM-213M |

|

English

English Russian

Russian Spanish

Spanish