Product List

Plastic Close-end Zipper Machinery (Auto Line)

- Auto Slider Mounting Machine (TYM-224D)

Auto plastic slider mounting machine is used for inserting sliders on zipper chains. Chain should be gapped before inserting sliders. The machine for two way open-end zipper is available....

Tag: Plastic Zipper Slider Mounting Equipment | Auto Plastic Slider Mounting Equipment | Auto Plastic Zipper Slider Mounting Machinery | Plastic Slider Mounting Zipper Equipment

- Auto Close-end Injection Molding Machine (TYM-235D)

Auto close-end injection molding machine is used for producing top stop, pin and box for plastic zippers. The top stop, pin and box can be made at the same time....

Tag: Close-end Injection Molding Equipment | Auto Close-end Injection Molding Machinery | Plastic Close-end Injection Molding Zipper Equipment | Auto Close-end Injection Molding Machine for Plastic Zipper

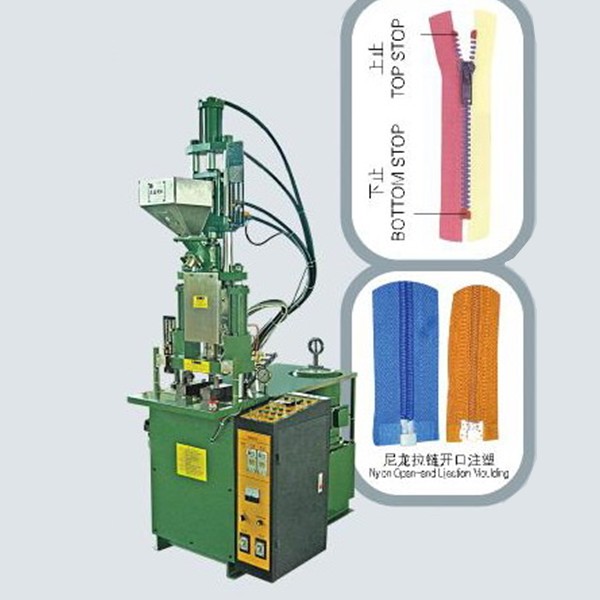

- Semi-auto Injection Molding Machine (TYM-206D)

Semi-auto injection molding machine is used for producing top stop, bottom stop or pin-box for plastic zippers. The top stop, bottom stop or pin-box can be made at the same time....

Tag: Semi-auto Injection Molding Zipper Machine | Semi-auto Plastic Zipper Injection Molding Machinery | Semi-auto Injection Molding Machine for Plastic Zipper | Semi-auto Plastic Injection Molding Zipper Making Machinery

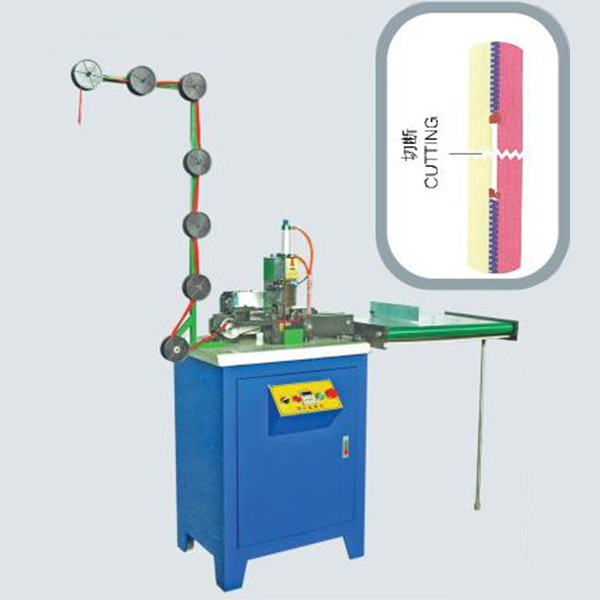

- Auto Zigzag Cutting Machine (TYM-211D)

Auto zigzag cutting machine is used for cutting plastic zipper chain into pieces in zigzag shape. The automatic device helps to reduce the labor cost and increase efficiency....

Tag: Plastic Zigzag Cutting Machine | Auto Zigzag Cutting Machine for Plastic Zipper | Auto Plastic Zigzag Cutting Machinery | Plastic Zigzag Cutting Equipment

Description

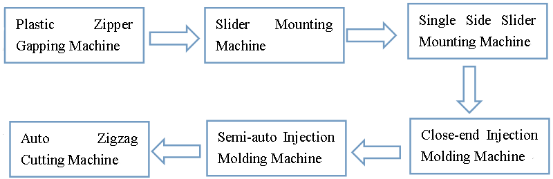

zipper gapping machine, slider mounting machine, single side slider mounting machine, close-end injection molding machine, semi-auto injection molding machine and auto zigzag cutting machine. These machines work together to finish close-end plastic zippers.Advantages of Plastic Close-end Zipper Machinery

1. Differential molding technology: Mold close at high speed. Mold nearly close with low speed and low pressure aims to protect the mold.2. Easily wearing parts for replacement will be offered free of charge one year for automatic machine, half a year for semi-auto machine.

3. High pressure generates after closing the mold to avoid burr and galling.

4. Extra spare parts of each machine will be packed in tool box and sent together with machine when make delivery.

5. With humanized design, hydraulic cylinders pull strip liner in and then lift barrel automatically, which is easy to clean up.

6. User-friendly control system in English with full-scale functions.

Note of Auto Plastic Close-end Zipper Line

1.The automatic machines works in high efficiency, helping to save lots of labor source and cost, while the efficiency of semi-auto machine is lower than automatic one, but they are more easier to operate and maintenance.2. Usually one worker can operate 3 to 4 automatic plastic close-end zipper machines at the same, while semi-auto machines need one worker for each machine.

(The choice of automatic machine or semi-auto machine depends on customer’s actual situation.)

Flow Chart of Auto Plastic Close-end Zipper Line

Machines used for Auto Plastic Close-end Zipper Line in Tianyi

| 1.TYM-210D | 2.TYM-224D | 3.TYM-224S |

| 4.TYM-235D | 5.TYM-206D | 6.TYM-211D |

English

English Russian

Russian Spanish

Spanish