Product List

Plastic Open-end Zipper Machinery (Auto Line)

- Auto Plastic Zipper Gapping Machine (TYM-210D)

Auto plastic zipper gapping machine is for gapping and cleaning the teeth for nylon zipper chain.Zipper length is set as customer's requirement....

Tag:

- Auto Ultrasonic Film Welding Machine (TYM-205D)

Auto ultrasonic film welding machine is capable of welding double films for plastic zipper after gapping. The equipment features high efficiency, which films will be welded firmly in 0.2 to 0.3 seconds....

Tag: Plastic Ultrasonic Film Welding Zipper Making Machinery | Auto Film Welding Zipper Machine | Auto Ultrasonic Film Welding Equipment for Plastic Zipper | Film Welding Zipper Making Equipment

- Auto Open-end Punching Machine (TYM-209D)

Auto open-end punching machine is used for punching holes on plastic zipper for setting pins and boxes. The automatic device helps to reduce the labor cost and increase efficiency....

Tag: Plastic Zipper Punching Equipment | Auto Open-end Punching Machine for Plastic Zipper | Auto Plastic Punching Zipper Making Equipment | Plastic Punching Zipper Machinery

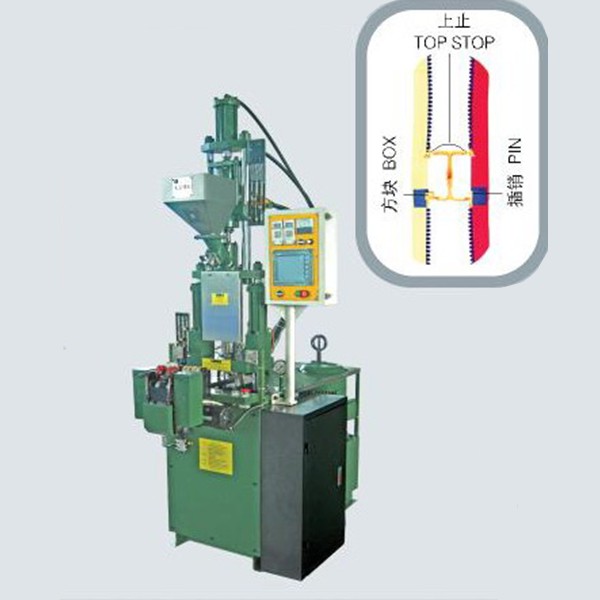

- Auto Open-end Injection Molding Machine (TYM-208D)

Auto open-end injection molding machine is used for producing top stop, pin and box for plastic zippers. The top stop, pin and box can be made at the same time. The machine is powered by hydraulic drive and assist with air pressure....

Tag: Plastic Open-end Injection Molding Equipment | Auto Open-end Injection Molding Equipment | Auto Open-end Injection Molding Machine for Plastic Zipper | Plastic Open-end Injection Molding Machinery

- Auto Open-end Zipper Injection Molding Machine (TYM-228A)

Auto open-end injection molding machine is used for producing top stop, pin and box for plastic zippers. The top stop, pin and box can be made at the same time....

Tag: Plastic Injection Molding Equipment | Auto Open-end Injection Molding Machinery | Plastic Open-end Injection Molding Machines | Plastic Open-end Injection Molding Zipper Equipment | Auto Open-end Injection Molding Equipment for Plastic Zipper

- Auto Open-end Cutting Machine (TYM-220D)

Auto open-end cutting machine is used for cutting zipper chain into pieces in straight shape. It is with various kinds of sliders....

Tag: Open-end Cutting Equipment for Plastic Zipper | Plastic Zipper Cutting Making Equipment | Plastic Open-end Zipper Cutting Machines | Auto Open-end Plastic Zipper Cutting Machines

Description

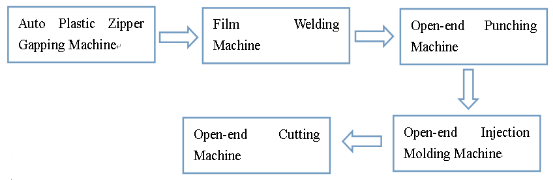

plastic zipper gapping machine, film welding machine, open-end punching machine, open-end injection molding machine and open-end cutting machine. These machines work together to finish open-end plastic zippers.Advantages of Plastic Open-end Zipper Making Machine

1. Main electric components are from Japan, Germany, Taiwan, etc, in order to ensure longevity and stability.2. Extra spare parts of each machine will be packed in tool box and sent together with machine when make delivery.

3. With easy operation and reasonable design, the hole can be accurately molded without damaging the zipper tape.

4. Controllable time and quantity: the cutting machine will stop after cutting the required pieces in setting time. It will restart after a few minutes.

Note of Auto Plastic Open-end Zipper Line

1. The automatic machines works in high efficiency, helping to save lots of labor source and cost, while the efficiency of semi-auto machine is lower than automatic one, but they are easier to operate and maintenance.2. Usually one worker can operate 3 to 4 automatic plastic open-end zipper making machines at the same time, while semi-auto machines need one worker for each machine.

(The choice of automatic machine or semi-auto machine depends on customer’s actual situation.)

Flow Chart of Auto Plastic Open-end Zipper Line

Machines used for Auto Plastic Open-end Zipper Line in Tianyi

| 1.TYM-210D | 2.TYM-205D | 3.TYM-209N |

| 4.TYM-208D or TYM-228A | 5.TYM-220D |

|

English

English Russian

Russian Spanish

Spanish